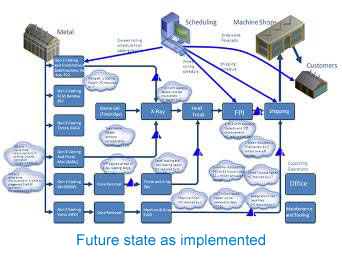

Comprehensive intervention improving capacity of labour-intensive X-ray and FPI inspection lines, reducing operating shifts from 4 to 2. Improvement of casting OEEs from 50% to 80%, enabling additional reduction of operating shifts. Plant manager coaching to establish highly effective problem solving skills within the organisation. Participation of the entire workforce in LIFTs, averting the imminent closure of the operation. Major new contracts from European luxury automotive producers have been realized.

Comprehensive intervention improving capacity of labour-intensive X-ray and FPI inspection lines, reducing operating shifts from 4 to 2. Improvement of casting OEEs from 50% to 80%, enabling additional reduction of operating shifts. Plant manager coaching to establish highly effective problem solving skills within the organisation. Participation of the entire workforce in LIFTs, averting the imminent closure of the operation. Major new contracts from European luxury automotive producers have been realized.

The Restructured line for final inspection bypassed a parts-transfer mechanism improving Overall Equipment Effectiveness (OEE) by 30%. With other improvements overall labour requirements for this line was reduced by 50%.

- Project timeline: 20 weeks

- Project cost: $485,267

- Project savings: $10,100,000

- Return on Investment: 20