Comprehensive intervention focusing on improving production and packing cell design, distribution centre systems improvements including a visual kanban system and an internal milk-run system, various process kaizen/LIFT events, scrap reduction, process yield improvements, material and energy cost savings.

- Project timeline: 35 weeks

- Project cost: $386,453

- Project annualized savings: $4,000,000

- Return on Investment: 10.4

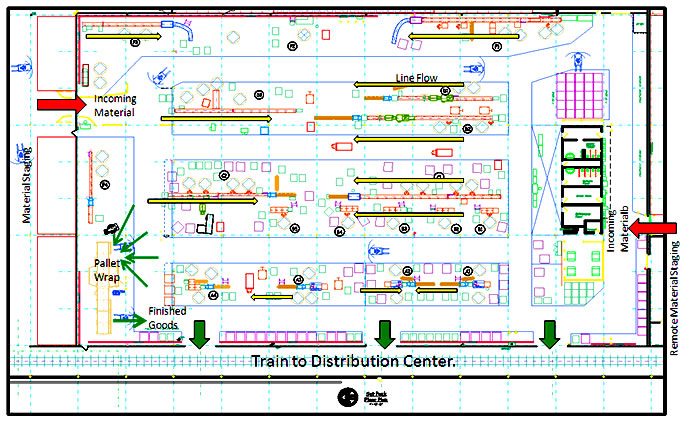

Previous Layout and Material Flow

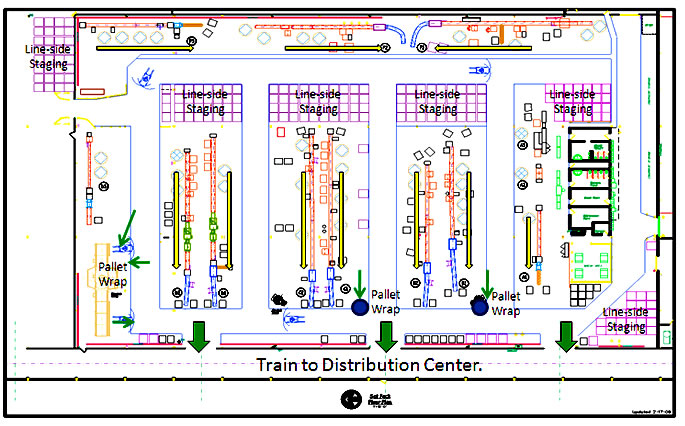

Current Layout

Improvements

- Improved material flow (also increased safety)

- Direct line-side staging of raw materials

- Forklift operate milkrunsin zones, one less driver needed

- Lines dedicated to families

- Offloading can be staffed by one operator

- Andon and material call installed

- Improved standardized work and line balance on a product family basis with major efficiency gains

- Daily management system put in place