Download Resources

For More Info - Call Us

|

+ 1-502-322-6567 |

Quick Changeovers / Set-up Reduction

Description

At many operations, setup reduction is a key tool for establishing work flow. This course will teach participants how to develop a “pit crew” to execute standardized, rapid, low-variability setups that ensure process readiness and production quality. We will develop and document setup procedures using hands-on exercises that translate easily to workplaces. This is usually conducted over 1½ to 2 days and should include an ILS-led setup reduction activity in your plant to enhance the learning, ensure capability of the team to apply what they have learned across your operations and provide immediate return on your training investment.

Objectives & Outcomes

- Prioritize setup reduction activities to have maximum impact

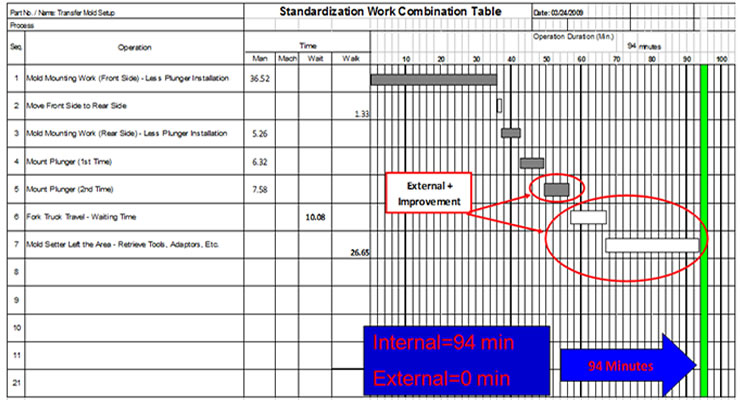

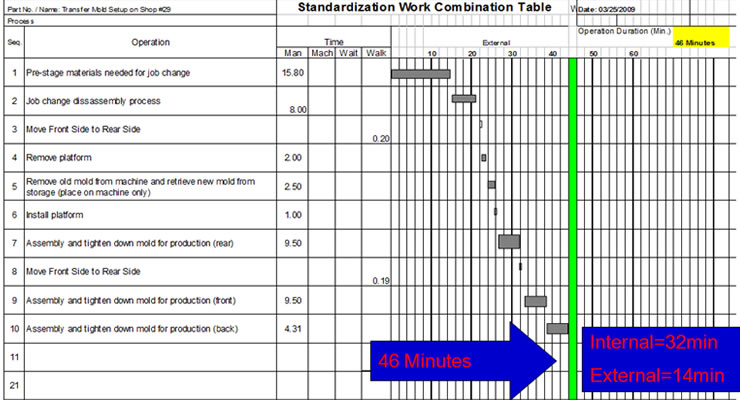

- Describe foundational concepts, including internal versus external activities and the importance of variability reduction

- Document and analyze the current state method

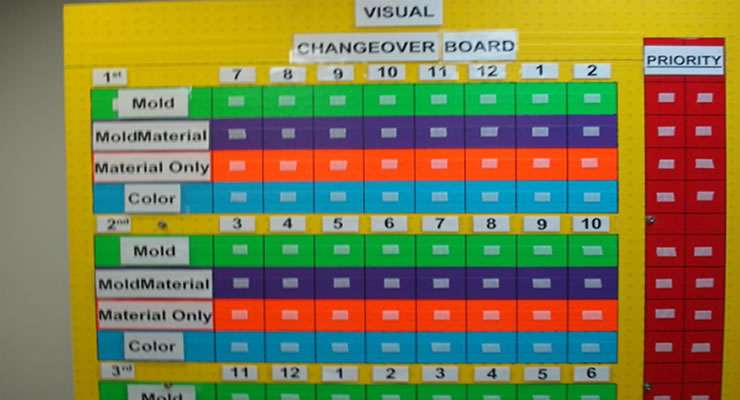

- Develop standardized external operations including 5S to support setup, readiness verification systems and setup carts or pre-positioning systems

- Describe strategies to convert internal operations to external operations including rapid transitioning of machine operating parameters, functional analysis, standardized interfaces, tool presetting, principles of fixture design for rapid changeover and gauging systems

- Analyze tooling to define setup families and optimum run sequences, including preferred run sequences for processes under pull production control

- Design rapid disconnect methods

- Establish procedures to eliminate or minimize process adjustment, including the use of design of experiments

- Design parallel work activities to reduce internal downtime

- Coordinate a setup reduction event

- Document standardized setup procedures, including concurrent activities

- Sustain and improve setup procedures

- Use auditing systems and setup control boards

Target Audience

This course is designed for a team of individuals charged with development of rapid changeover procedures and execution of those procedures in the work place. This might include a mix of setup operators, process operators, maintenance technicians, production engineers, operations supervisors and tooling specialists.

Copyright © 2018 ILS | All rights reserved.